Testing & Certifying

Controlled Products' ability to establish itself as one of the most innovative manufacturers of artificial grass in the world stems from its Research, Development and Quality Control Laboratory…also known as "The Lab".

Our Technology

We leave no detail overlooked, using state-of-the-art technology to ensure every product meets the highest standards of quality and performance.

Lisport

- Simulates wear and tear

- Durability

- Excellent for comparing products during the R&D process.

Instron

- Measures tuft bind - The force needed to pull the yarn from the backing of the turf

- Tensile Strength - Ensures top quality yarn and consistency

- Delamination test - Measures force required to delaminate products

Weight Checks

- Die and scale

- Quality Control

- Confirms product has +/-0.5% of the correct amount of Silverback™ coating applied during the coating process

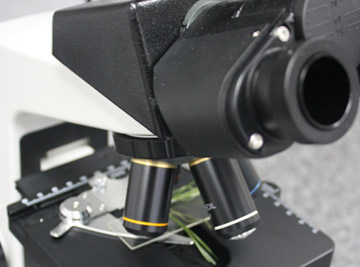

10mp Microscope Camera

- Shows the microscopic effects of wear and tear on the yarn of the turf

- Visually inspects effects of outside elements

- Allows us to view the quality and cellular composition of our Silverback™ coating

High Speed Curing Oven

- Assists in the new product development process

- Allows curing of test products

- Allows curing of small samples of Silverback™ coating to ensure we provide you with a quality product

Golf Mat Tester

- Tests durability and longevity of golf hitting mats

- Notes any residue pickup from blades to irons

- Shows turf's ability to replicate "down-and-through" swing

Talk to a Turf Specialist

Speak to a knowledgeable Turf Specialist who will help select the ideal turf for your needs.